Firmamız tedarikçilerimizden gelen her türlü hammadde ve yardımcı malzemelere belirlenen kalite ve üretim standartlarına göre Giriş Kalite Kontrol testleri uygulanarak sonra hammaddenin ve yardımcı malzemenin “Üretime Uygundur” onayı alması zorunludur

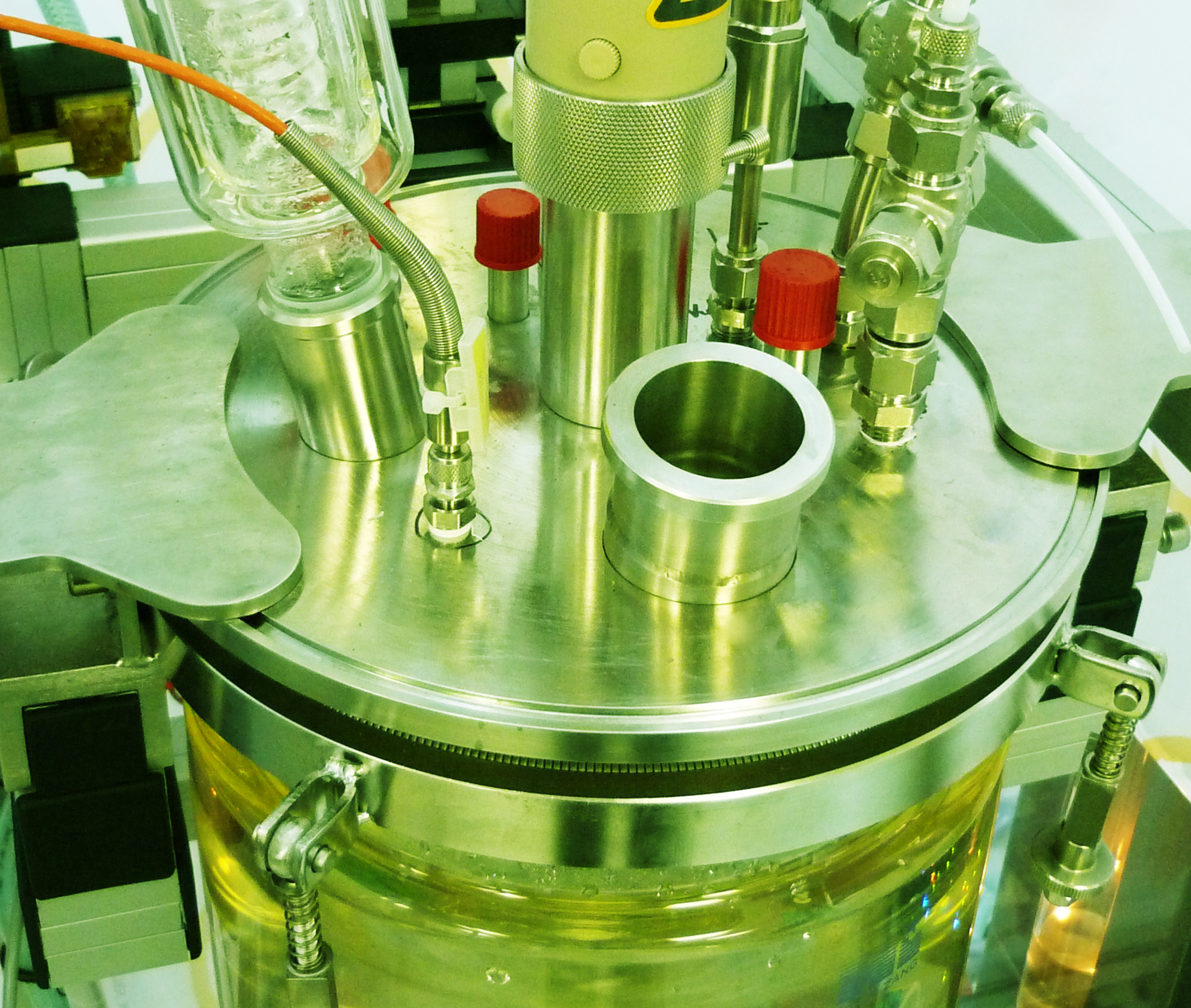

In the production process carried out with raw materials and auxiliary materials that have the approval of Suitable for Production, samples taken during and immediately after production on the production lines are subjected to Process Quality Control tests determined by national (TSE) and international (EN, DIN, ISO etc.) quality standard institutions in our company's laboratories and are regularly recorded.

In the Process Quality Control stage, product measurements are continuously checked and recorded simultaneously with production. It is mandatory for our products to receive "Quality Approval" by passing all controls made in accordance with the frequency and number of controls specified in the quality standards.

Sufficient Working Area

Separation of separate sections of sufficient width so that the products produced and the raw materials belonging to these products do not mix with each other,

The production site is divided into a storage area for products and raw materials, a raw material acceptance area specific to products allocated for testing, and an area allocated for rejected raw materials.

Production Process and Control

The entire production process is carried out under the supervision of authorized technical personnel.

All containers, containers and mechanical production equipment are checked and labeled in terms of the characteristics of the product produced. And the batch number is given.

Quality Control System

Our expertly trained quality control personnel check raw materials and finished products.

Our quality control laboratory systematically performs the following main tasks.

Writing a detailed report of each test and analysis performed.

Reports are prepared for each product that is accepted or rejected.

One piece from each batch of raw materials and final products is kept for future return evaluation and control.

The stability of raw materials and finished products is evaluated.

Returned products are transformed and reused after the necessary checks are made and the reasons are reported.

Raw Material Checks

After the necessary shipping documents and shipping numbers are checked and the external appearance is inspected, they are accepted to the factory. (Possible deformations during transportation are checked)

The raw material is stored at a temperature and humidity appropriate to its characteristics.

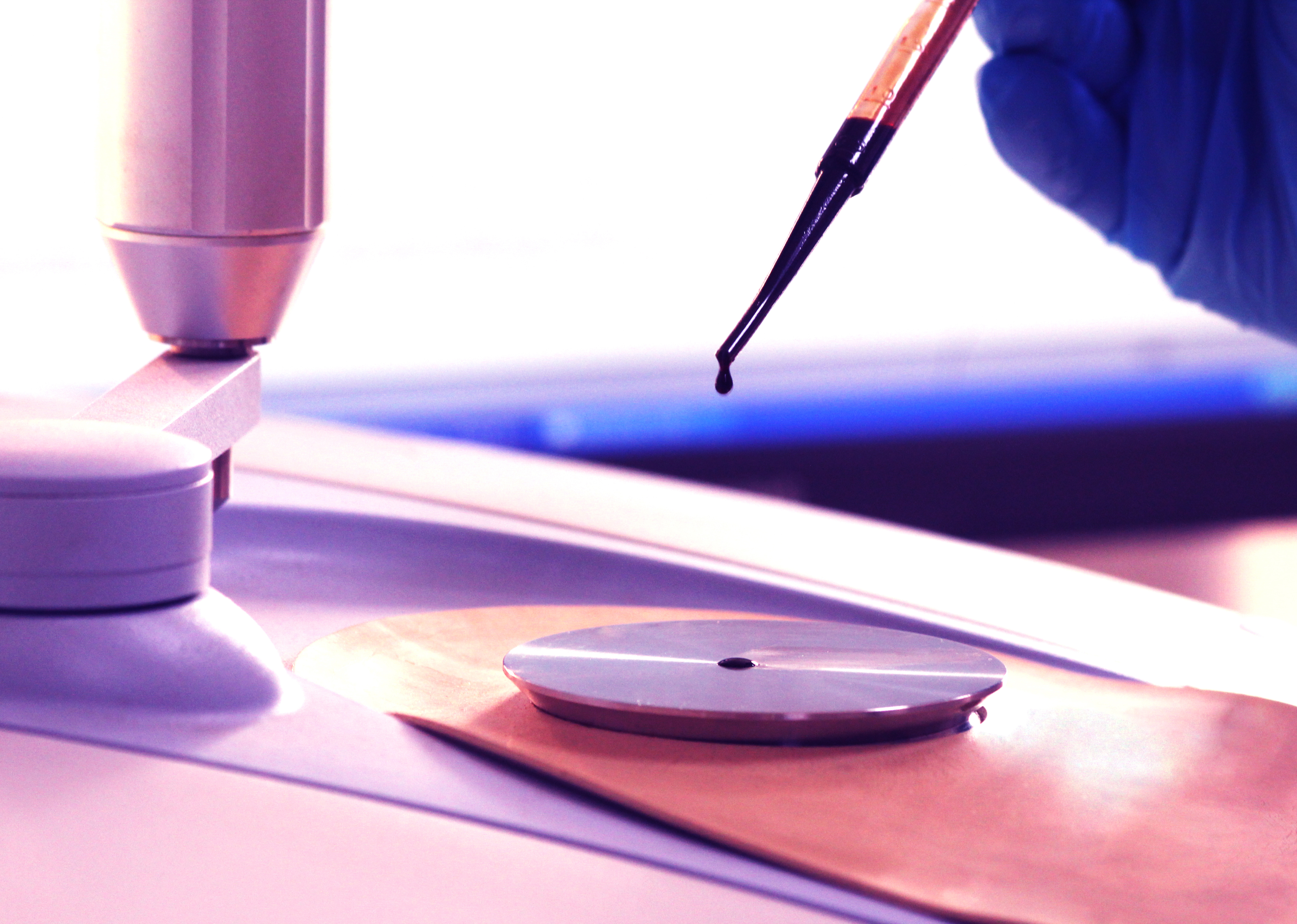

Sampling is systematically taken by quality control personnel and their checks are carried out in terms of compliance with the standards.

Sampling

At every stage of the production process, samples are taken in accordance with the standards within the framework of the quality plan.

Samples are taken from the purchased raw materials, from the reactors during the production phase and during the product shipment.

Spot (instant) sampling and product control are carried out from the product shipment points in accordance with EN norms.

Samples taken during shipment are kept as witness samples.

Sample Preparation

In laboratories, samples are subjected to a preparation process before analysis. These processes consist of reducing the sample to a representative amount, weighing, mixing, etc.

The label indicating the product features is prepared according to the relevant standard and sent to the customer with its technical documents.

The sample is placed in a tightly closed container, the lid is taped, and then placed in 2 bags and sent.

Calibration

Calibration of all test equipment and devices is performed periodically by internationally recognized calibration organizations within the framework of a documented calibration plan.