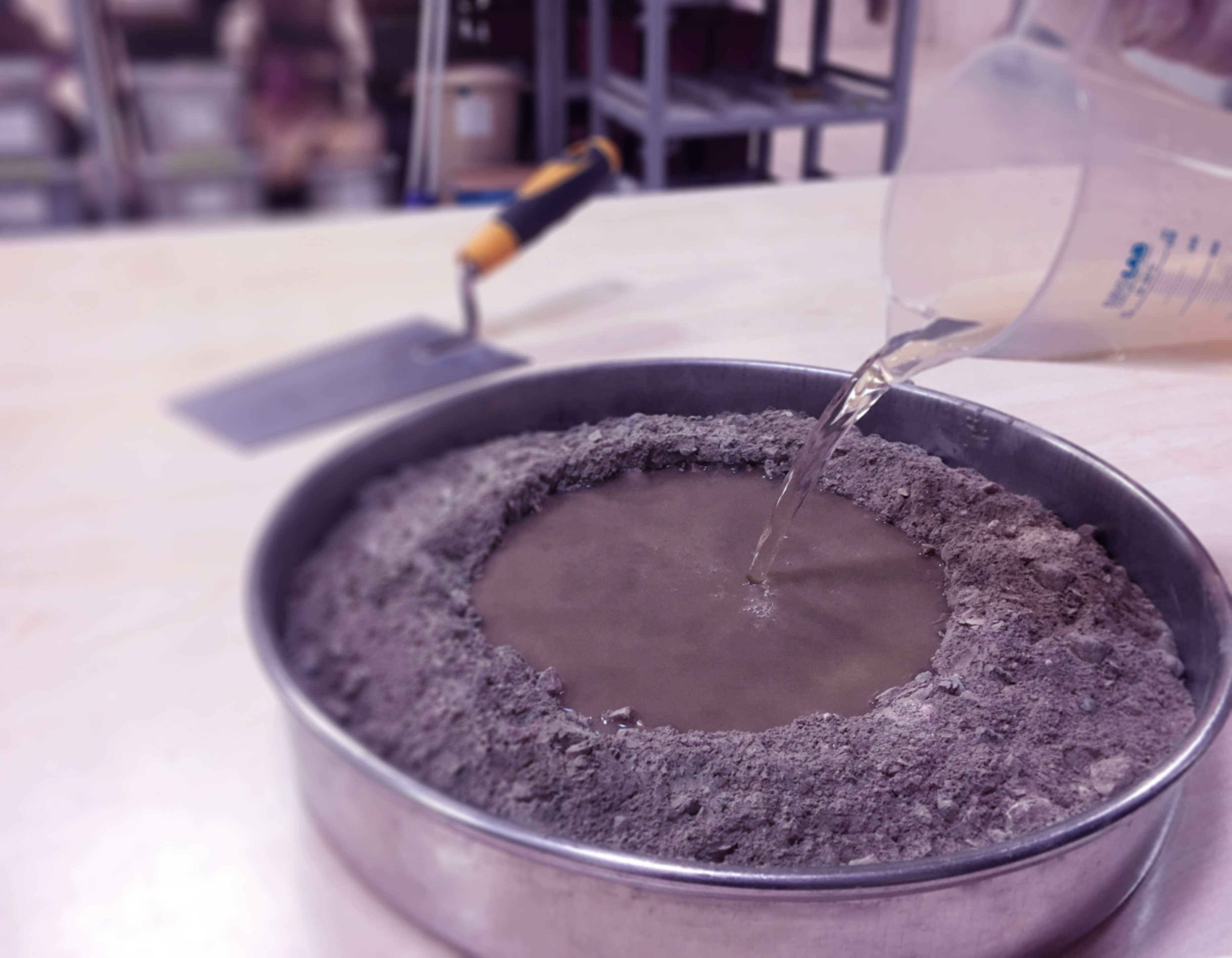

MIXING WATER FOR CONCRETE

Mixing water is a very sensitive and important raw material used in concrete to ensure workability and cement hydration. Its sensitivity and importance stem from the fact that the amount of water can affect all the properties of both fresh and hardened concrete.

Concrete mixing water should be as clean as possible and should not contain harmful substances such as chlorides, sulfates, acids, sugars, organic materials, industrial waste, oil, clay, or silt in quantities that could negatively affect the concrete.

Cement requires water equal to approximately 25% of its weight for hydration. Any additional water used beyond this amount is solely intended to increase the workability of the concrete. However, this excess water eventually leaves the concrete structure, resulting in voids. The more mixing water used, the more voids are formed, which not only reduces the strength of the concrete but also negatively affects its durability.

In concrete production, water is used for three different purposes:

As mixing water, together with cement and aggregates during the mixing of concrete,

As curing water, applied to the surface of freshly placed concrete,

As washing water, to ensure that the aggregates used in concrete are clean.

Among these, the most important is the first one. In other words, the primary purpose is to wet the surface of the cement and aggregate particles to allow the concrete materials to be easily mixed and placed — essentially, to ensure workability.